|

| |

|

EFIE

Electronic Fuel Injection

Enhancer

|

| So, you are thinking of using Hydrogen and

Oxygen as an additive to your gasoline engine, and you are wondering if you

need to invest in an EFIE device. That is not an easy question to answer. In the past, fuel savers would not work when

applied to fuel systems that use oxygen sensor feedback circuits. These systems

were designed to prevent efficient combustion, by lowering and controlling the air mixture

of the engine from 14.7 parts to 14.5 parts of air for each part of fuel!

This was done to reduce Carbon Monoxide and NOX emissions in the engines

exhaust, and to make your engine use more gas. The EPA then made auto

manufacturers add expensive Catalytic Converters to the exhaust systems in

order to get rid of the unburned fuel. To date, this is one of the biggest

Scams ever pulled on the public. We fell for it, hook, line, and sinker. To

beat all, it is computer controlled. If enough hydrocarbons are not measured

in the exhaust, the computer sends more gasoline. This is the number one

reason why most Fuel Saving Devices Do Not Work.

Increasing the combustion efficiency of the engine changes the percentage of

oxygen in the exhaust because the engine uses less fuel for the same volume

of air and the engine produces less carbon

monoxide and oxides of Nitrogen. Oh, we can't have that (so says the EPA).

The increased oxygen content in the exhaust is read by the computer to be

a lean mixture in the engine. As a result, the computer then adds extra fuel

to bring the pollution back to normal. In other words, when the computer

sees extra oxygen in the exhaust, it sends enough fuel to maintain a 14.5

parts air to 1 part fuel ratio. When the computer sees less oxygen in the

exhaust, it backs off on the fuel to maintain a 14.5 to 1 fuel ratio. The EFIE's function is to modify the oxygen sensor's output-signal

to the computer - by adding a

floating voltage; so the computer will not see the extra oxygen.

If you plan on using Hydrogen and Oxygen as an additive, one way or

another, the air fuel ration will have to be dealt with, if you want better

fuel mileage. Hydrogen as an additive works. Oxygen as an additive works.

They both provide better, more complete, combustion of the fuel. They both

decrease harmful exhaust emissions. Period. It is a proven fact.

It is the

computer controlled Emissions Control System that reverses the positive

benefits of HHO.

The EPA has been slowly passing tamper laws. It is unlawful to tamper

with the Emission Control Sensors. These laws are going to be enforced,

starting January 1, 2011. But

there are no laws against reprogramming an Emissions Control System as long

as the EPA standards are met or improved. That is the reason I chose the

Volo Chip for my Ford modification. The chip replaces the ECM settings, in

order to change and maintain better Air Fuel mixtures, based on driving

conditions. If you have a 1996 through 2009 vehicle with an OBD-2

Emissions Control System, then the Volo may be good choice for a lot of

vehicles. I say may, because it is turning out that it is not the solution

for a lot of vehicles. It falls short. The ECM works around it somehow. If your vehicle is year 1987 through 1995, you probably have an

OBD-1 Emissions Control System. OBD-1 systems usually need an EFIE; but not

always. Some respond by injecting the HHO in front of the MAF sensor, so

that the HHO must pass through the MAF sensor (if they have a MAF). Some of these vehicles accept HHO without any changes,

just by resetting the computer; most do not. Reset the computer by

disconnecting the battery for a few minutes. It causes the computer to

relearn the fuel mixture. |

| |

|

Which EFIE do I

need?

Which EFIE do I

need?

Sensor Request Form (find out what sensors you have and what Type they

are)

Sensor Request Form (find out what sensors you have and what Type they

are)

About Oxygen Sensors

About Oxygen Sensors

Oxygen Sensors, How to Diagnose and Replace

Oxygen Sensors, How to Diagnose and Replace

OBD1 Vehicles, pre- 1996

OBD1 Vehicles, pre- 1996

HHO Shortcuts

HHO Shortcuts

|

| |

|

|

5 Types of Oxygen Sensors |

| |

|

|

Unheated Thimble-type O2

Sensors (LS)

Bosch introduced this design in 1976 for feedback fuel control on automotive

engines. The zirconia ceramic "thimble" is encased in a protective tube

which extends into the exhaust manifold. Slots in the protective tube allow

hot exhaust gases to reach the thimble. Reference outside air for the

interior of the thimble comes from a hole in the sensor shell, or through

the wiring connector. Unheated O2 sensors rely only on the heat of the

exhaust gases to reach operating temperature, therefore they might cool off

while the engine is idling and revert back to a fixed air/fuel ratio

setting. This type of sensor generally has a single wire connector, though

some have two.

Heated Thimble-type O2 Sensors

(LSH)

Introduced by Bosch in 1982, this sensor adds a heater element to the

original design so that the sensor achieves operating temperature in 30-60

seconds, instead of being heated by exhaust gases. It has a separate

electric circuit for the heater, so look for 3 or 4 wire connectors to

distinguish this unit. The heater reduces cold start emissions, as well as

prevents the sensor from cooling off at idle.

Heated Titania-type O2 Sensors

Titania sensors use a different type of ceramic and instead of generating a

voltage signal that changes with the air/fuel ratio, the sensor's electrical

resistance changes. The resistance is less than 1000 ohms when the air/fuel

ratio is rich, and more than 20,000 ohms when the air/fuel ratio is lean.

The ECU provides a base reference voltage and then monitors the sensor

return voltage as the sensor's resistance changes. Titania O2 sensors are

used on less than 1% of O2 sensor-equipped vehicles:

-

86-'93 Nissan 3.0L trucks

-

'91-'94 Nissan 3.0L Maxima,

2.0L Sentra

-

'87-'90 Jeep Cherokee,

Wrangler, and Eagle Summit

Heated Planar-type O2 Sensors

(LSF)

Introduced by Bosch in 1997, this O2 sensors uses a laminated flat strip

of conductive ceramic, electrodes, insulation, and heater. This sensor is

smaller and lighter, and more difficult to contaminate. The new heater uses

less electricity and brings the sensor to the proper temperature in 10

seconds. Outside reference air is supplied by a small port in the center of

the ceramic strip where the 4 electrical wires connect. By model year 2004,

planar O2 sensors are expected to account for 30% of all O2 sensor

applications and by 2008, for up to 75%. The following list shows the

inclusion of more and more models:

-

1998: VW 2.0L New Beetle

-

1999: Cadillac Catera, Saturn

3.0L LS, VW 2.0L Jetta

-

2000: All Audis exc. A4 1.8L

turbo and A6 2.8L; California Dodge 2.0L Neon; Ford 4.0L and 5.0L

Explorer; Ford 2.5L LEV Ranger; Ford 3.8L Windstar; MBZ 3.2L ML320 and

4.3L ML430; Mercury 4.0L & 5.0L Mountaineer; Saab 2.0L & 2.3L; and all

VW and Volvo models

-

2001: Porsche 911 3.6L Turbo;

all MBZ models exc. SL500 and SL600

-

2002: All Audis, All Dodge

Neons, all Ford F-Series trucks (4.2L, 4.6L, 5.4L), all Ford Ranger

trucks, Mazda B-Series pickups (2.5L, 3.0L & 4.0L), all MBZ models and

Saturn 3.0L SUV

Heated Wide-Band O2 Sensors

(LSU) (from the November 2001 Bosch Reporter)

The newest O2 sensor technology from Bosch builds

upon the planar design and adds the ability to actually measure the air/fuel

ratio directly for the first time. Instead of switching back and forth like

all previous sensor designs, the new wide-band O2 sensor produces a signal

that is directly proportional to the air/fuel ratio.

The wide-band sensor uses a "dual

sensing element" that combines the Nernst effect cell in the planar design

with an additional "oxygen pump" layer and "diffusion gap" on the same strip

of ceramic. The result is a sensor element that can precisely measure

air/fuel ratios from very rich (10:1) to extremely lean (straight air). This

allows the engine computer to use an entirely different operating strategy

to control the air/fuel ratio. Instead of switching the air/fuel ratio back

and forth from rich to lean to create an average balanced mixture, it can

simply add or subtract fuel as needed to maintain a steady ratio of 14.7:1.

Like a zirconia thimble or

planar-type sensor, the wide-band sensor produces a low-voltage signal when

the air/fuel ratio goes lean, and a high-voltage signal when the mixture is

rich. But instead of switching abruptly, it produces a gradual change in the

voltage that increases or decreases in proportion to the relative richness

or leanness of the air/fuel ratio. So, at a perfectly balanced air/fuel

ratio or 14.7:1, a wide-band O2 sensor will produce a steady 450 mv. If the

mixture goes a little richer or a little leaner, the sensor's output voltage

will only change a small amount instead of rising or dropping dramatically.

Another difference in the

wide-band O2 sensor is the heater circuit. Like a planar sensor, it is

printed on the ceramic strip. But the heater circuit is pulse-width

modulated to maintain a consistent operating temperature of 1292 to 1472

degrees F. the sensor takes about 20 seconds to reach operating temperature.

Reference:

http://tayloredge.com/reference/Science/oxygensensor2.pdf

Note: There are two types of narrowband sensors

- Zirconia and Titania. Titania is used in Jeeps and off-road vehicles,

especially. Please read this link to understand the difference

http://www.ngk.com/sparkplug411.asp?kw=Titania&mfid=1

|

|

Bosch Wideband Oxygen Sensors Precisely Measure Air/Fuel

Ratios |

| |

|

Wideband Oxygen Sensors

As engine management and on-board diagnostic systems continue to

evolve, so too do the oxygen sensors that monitor the air/fuel mixture. The

latest generation of "wideband" oxygen sensors from Robert Bosch are

smarter, faster, more durable and capable of precisely measuring exact

air/fuel ratios - a feat that was impossible with earlier generations of O2

sensors.

Traditionally, oxygen sensors have

been used to monitor the level of unburned oxygen in the exhaust.The amount

of oxygen that's left in the exhaust following combustion is a good

indicator of the relative richness or leanness of the fuel mixture.

When air and gasoline are mixed

together and ignited, the chemical reaction requires a certain amount of air

to completely burn all of the fuel. The exact amount is 14.7 lbs of air for

every pound of fuel. This is called the "stoichiometric" air/fuel ratio.

It's also referred to the the Greek letter "lambda."

When lambda equals one, you have a

14.7:1 stoichiometric air/fuel ratio and ideal combustion. When the air/fuel

ratio is greater than 14.7:1, lambda also will be greater than one and the

engine will have a lean mixture.

Lean mixtures improve fuel economy

but also cause a sharp rise in oxides of nitrogen (NOX). If the mixture goes

too lean, it may not ignite at all causing "lean misfire" and a huge

increase in unburned hydrocarbon (HC) emissions. This can cause rough idle,

hard starting and stalling, and may even damage the catalytic converter.

Lean mixtures also increase the risk of spark knock (detonation) when the

engine is under load.

When the air/fuel ratio is less

than 14.7:1, lambda also is less than one and the engine has a rich fuel

mixture. A rich fuel mixture is necessary when a cold engine is first

started, and additional fuel is needed when the engine is under load. But

rich mixtures cause a sharp increase in carbon monoxide (CO) emissions.

When the relative proportions of

air and fuel are "just right," the mixture burns clearly and produces the

fewest emissions. The trick is balancing the mixture as driving conditions,

temperatures and loads are constantly changing. That's where oxygen sensors

come in.

By monitoring the level of

unburned oxygen in the exhaust, the sensor(s) tell the engine computer when

the fuel mixture is lean (too much oxygen) or rich (too much fuel). To

compensate, the computer adjusts the fuel mixture by adding more fuel when

the mixture is lean, or using less fuel when it is rich.

That's the basic feedback fuel

control loop in a nutshell. The trouble is, conventional oxygen

sensors give on a rich-lean indication. They can't tell the computer the

exact air/fuel ratio. When the air/fuel ratio is perfectly balanced, a

convention O2 sensor produces a signal of about 0.45 volts (450 millivolts).

When the fuel mixture goes rich, even just a little bit, the O2 sensor's

voltage output shoots up quickly to its maximum output of close to 0.9

volts. Conversely, when the fuel mixture goes lean, the sensor's output

voltage drops to 0.1 volts.

Every time the oxygen sensor's

output jumps or drops, the engine computer responds by decreasing or

increasing the amount of fuel that is delivered. This rapid flip-flopping

back and forth allows the feedback fuel control system to maintain a

more-or-less balanced mixture, on average. But this tried-and-true approach

that has worked so well thus far isn't accurate enough to meet the latest

emissions requirements.

The new NLEV (national low

emission vehicle) standards plus California's LEV (low emission vehicle),

ULEV (ultra low emission vehicle) and SULEV (super ultra low emission

vehicle) standards all require very precise control over the air/fuel ratio.

Reducing cold emissions when the engine is first started is absolutely

critical to meeting these standards. But conventional oxygen sensors (even

with heaters) warm up too slowly to provide the degree of accuracy needed to

meet cold emissions. They also lack the ability to tell the PCM the exact

air/fuel ratio, something that is becoming increasingly necessary as

advanced fuel control strategies are introduced. A simple rich

The Wideband Air/Fuel Sensor

The newest generation of oxygen sensors

are being called "wideband" lambda sensors or "air/fuel ratio sensors"

because that's exactly what they do. They provide a precise indication of

the exact air/fuel ratio, and over a much broader range of mixtures - all

the way from 0.7 lambda (11:1 air/fuel ratio) to straight air!

The Bosch LSU 4 wideband oxygen

sensor is a 5-wire sensor that reads oxygen in much the same way as a

traditional oxygen sensor. but it uses the latest "planar" construction with

a special two-part sensing element to measure how much oxygen is in the

exhaust.

In 1997, Bosch developed a new

type of construction for oxygen sensors that uses a flat ceramic zirconia

element rather than a thimble. It's called a "planar" sensor because the

sensor element is a flat strip of ceramic that is only 1.5mm thick. The

electrodes, conductive layer of ceramic, insulation and heater are laminated

together on a single strip. The new design works the same as the

thimble-type zirconia sensors, but the "thick-film" construction makes it

smaller and lighter, and more resistant to contamination. The new heater

element also requires less electrical power and brings the sensor up to

operating temperature in only 10 seconds.

In creating the new LSU 4 wideband

air/fuel ratio sensor, Bosch combined the oxygen-sensing "Nernst" cell from

the planar sensor with an "oxygen pump" to create a device that can actually

measure air/fuel ratios. Here's how it works:

The Nernst cell still senses

oxygen in the same way that a conventional thimble-type O2 sensor does. When

there's a difference in oxygen levels across the zirconium dioxide sensor

element, current flows from one side to the other and produces a voltage.

But, as we said earlier, this isn't good enough because it gives only a

gross rich-lean indication of the air/fuel mixture.

To get the added precision, the

oxygen pump uses a heated cathode and anode to pull some oxygen from the

exhaust into a "diffusion" gap between the two components. The Nernst cell

and oxygen pump are wired together in such a way that it takes a certain

amount of current to maintain a balanced oxygen level in the diffusion gap.

And guess what? The amount of current required to maintain this balance is

directly proportional to the oxygen level in the exhaust. This gives the

engine computer the precise air/fuel measurements it needs to meet the new

emission requirements.

The wideband oxygen sensor

receives a reference voltage from the engine computer and generates a signal

current that varies according to the fuel mixture.

When the air/fuel mixture is

perfectly balanced at 14.7:1 (the stoichiometric ratio and lambda equals 2),

the sensor produces no output current. When the air/fuel mixture is rich,

the sensor produces a "negative" current that goes from zero to about 2.0

milliamps when lambda is 0.7 and the air/fuel ratio is near 11:1.

When the air/fuel mixture is lean,

the sensor produces a "positive" current that goes from zero up to 1.5

milliamps as the mixture becomes almost air.

The Bosch LSU 4 wideband oxygen

sensor has a response time of less than 100 milliseconds to changes in the

air/fuel mixture, and reaches operating temperature of 700 to 800 degree

Centigrade (1,400 degree F) within 20 seconds or less using its internal

heater. This is nearly twice the operating temperature of a conventional

oxygen sensor.

Other Uses

Many performance engine builders and tuners have discovered the benefits of

using the wideband oxygen sensor technology to monitor air/fuel ratios.

Being able to see the actual air/fuel ratio at any given instant in time

allows the fuel mixture to be fine-tuned and adjusted on the fly - something

which previously could only be done on a dynamometer using expensive

equipment.

The air/fuel ratio is critical

with high performance, turbocharged and supercharged engines to make power

and to keep the engine from leaning out at high rpm and boost pressures. If

the mixture leans out, it can send the engine into self-destructing

detonation.

Reference:

http://tayloredge.com/reference/Science/oxygensensor3.pdf |

| |

|

Bosch Wideband Oxygen Sensor Diagnostics |

| |

|

Diagnostics

Because of the internal circuitry used in

a wideband oxygen sensor, you can't hook up a voltmeter or oscilloscope to

read the sensor's output directly. A wideband O2 sensor produces a current

signal that varies not only in amplitude but direction. That makes it quite

different from a conventional oxygen sensor that produces a voltage signal

that bounces back and forth between 0.1 and 0.9 volts.

The only way you can currently

diagnose a wideband oxygen sensor is through the vehicle's on-board

diagnostic system using a scan tool.

You can use the scan tool to read

the actual air/fuel ratio, and to check the sensor's response to changes

that should cause a change in the air/fuel ratio. Opening the throttle wide,

for example, traditionally causes a sudden and brief lean condition followed

by a richer mixture as the computer compensates. But with the new control

strategies made possible with wideband O2 sensors, the air/fuel ratio

remains steady when the throttle is snapped open.

The diagnostic strategies for

wideband O2 sensors vary from one vehicle manufacturer to another but, as a

rule, you'll get an oxygen sensor code if the sensor reads out of its normal

range, if the readings don't make sense to the computer (should indicate

lean when lean conditions exist, etc.) or if the heater circuit fails.

One thing to keep in mind about

wideband O2 sensors is that they can be fooled in the same way as a

conventional oxygen sensor by air leaks between the exhaust manifold and

head, and by misfires that allow unburned oxygen to pass through into the

exhaust. Either will cause the sensor to indicate a false lean condition

which, in turn, will cause the computer to make the engine run rich.

Other Wideband Sensors

It's important not to confuse Bosch wideband O2 sensors with those produced

by other OEM suppliers. With some other wideband O2 sensors (such as those

used in 1996 and newer Toyotas, for example), a scan tool will display a

"simulated" voltage reading between 0 and 1 volt. The actual voltage output

from the sensor is much higher, but the computer is calibrated to divide the

sensor's actual output by 5 to comply with OBD II regulations that require a

display reading of 0 to 1 volts (these regulations have since been revised

to allow the actual voltage to be displayed.)

Sensor Replacement

Bosch wideband oxygen sensors are designed for an operational life of

100,000 miles. Replacement should be needed only if the sensor has failed

due to unusual operating conditions, physical damage, or contamination.

Blowing a head gasket can allow silicon to enter the exhaust and contaminate

the sensor. Oil burning can allow phosphorus to enter the exhaust and

contaminate the sensor. If replacement is necessary, use the same type of

wideband sensor as the original.

Reference:

http://tayloredge.com/reference/Science/oxygensensor3.pdf |

| |

| |

|

|

|

| |

|

|

EFIE's |

|

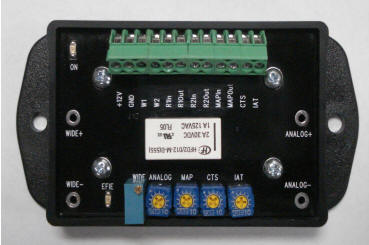

Tuning 101 AFR Control Center

Tuning 101 AFR Control CenterIf you

want to obtain the largest mileage gains possible...from any HHO Generator, you

must modify the signals from 4 sensor groups. Just doing the O2 Sensors,

with an EFIE, will not get it done on most vehicles.

This is the only product on the market that can get it done.

|

| |

Dual EFIE (Analog)

Dual EFIE (Analog)

An Electronic Fuel Injection Enhancer is used to adjust the signal from

the oxygen sensor before they get to the engine's computer to compensate for

an increase in fuel efficiency brought about by another fuel efficiency

device. The Dual version handles two oxygen sensor.

|

|

Digital EFIE

Digital EFIE

The Quad Digital EFIE Basic is the newest member of our family of EFIE's.

Digital EFIE's allow much leaner settings on vehicles than other types of

EFIE. We recommend Digital EFIE's for all narrow band oxygen sensors that are

upstream of the catalytic converter. Note, that the Quad EFIE uses a pair of

analog EFIE's for the downstream sensors. |

|

Frequency MAP /

MAF Enhancer Frequency MAP /

MAF EnhancerOur new frequency based MAP/MAF enhancer

is the first universal MAP/MAF Sensor Enhancer. It can be used for

devices that output a frequency to the computer, or devices that send an

analog voltage signal. |

| |

|

| |

|

Eagle-research EFIE - sold from their web site

Eagle-research EFIE - sold from their web site

EFIE Kit, unassembled - eagle-research.com

EFIE Kit, unassembled - eagle-research.com

EFIE, Assembled - eagle-research.com

EFIE, Assembled - eagle-research.com

Adjusting the EFIE (video)

Adjusting the EFIE (video)

Important:

Regardless of what you read elsewhere, this EFIE works on ALL types of

oxygen sensors, including Titania (varying resistance) sensors, A/F sensors

and wideband sensors. |

| |

|

| |

| |

|

|

EFIE Documentation

/Instructions/Tuning/etc. |

|

EFIE Circuit Schematic and Parts

List |

|

Dealing with the Vehicle Computer

(EFIE & MAP/MAF) |

| |

Page Last Edited

-

04/03/2022 |

|